Guided sieve tray has large process capability.

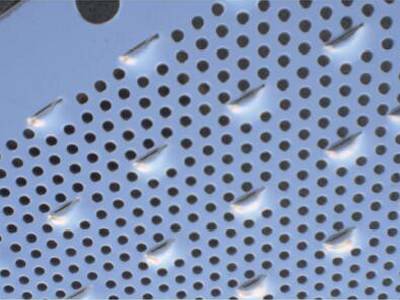

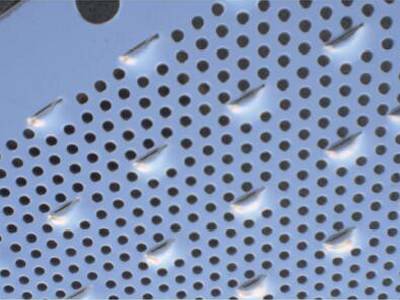

Guided sieve tray, whose screen-aperture diameter is typically 0.5 inch, is a basic type of fractionation tray. Vapor passes through a large number of sieves and emerges through the liquid in a vertical direction. This monolithic tower tray is composed by tower plate, downcomer, overflow dam, fasteners and supports. The structure of sieve tray is simple and easy to process and it is widely used in all sorts of industries due to its large process capability, moderate pressure drop, low cost and low maintenance requirements.

Compared with the normal sieve tray, the efficiency of guided sieve tray can increase by 10% to 30% and the operation flexibility will also increase by 10% to 20%.

Guided sieve tray has large process capability.

Guided sieve tray has strong anti-clogging ability.

| Model | Thickness (mm) | Weight (kg) |

|---|---|---|

| GSTS-01 | 1 | 14 |

| GSTS-02 | 1.5 | 25 |

| GSTS-03 | 2 | 33 |

| Materials: SS 304, SS 316, SS 316L, carbon steel. Guided sieve tray can be customized in different dimensions to meet customers' requirements. |

||

Features

Application

Sieve trays are widely used in plate towers, mainly including sieve-plate towers, bubble-cap towers and float valve tower. They can help gas and liquid bubble uniformly and provide heat-transfer and mass-transfer site for gas and liquid phrase.