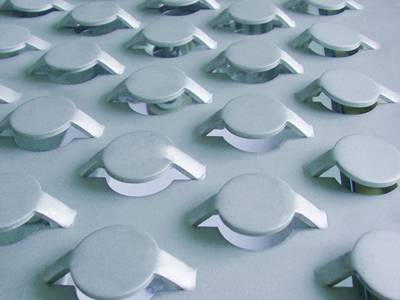

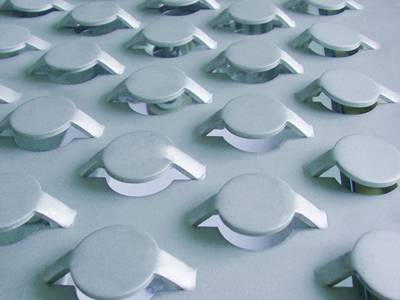

FVT-01: Fixed valves tray with advanced design can reduce entrainment.

Fixed valves tray is generally composed by 3 sections: bubbling area, weir and downcomer. The bubbling area is the place where vapor-liquid contact takes place and is also a high interfacial area for efficient vapor-liquid mass transfer. The function of a weir is to maintain a desired liquid level on the tray. Downcomers are used to guide liquid flow from an upper tray to a lower tray. Fixed valves tray is intended to give greater flexibility than sieve trays at a lower cost. It should be considered if the specified turndown ratio cannot be met with sieve trays.

FVT-01: Fixed valves tray with advanced design can reduce entrainment.

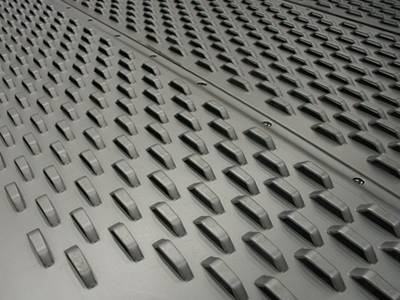

FVT-02: Fixed valves tray can be customized upon customers' needs.

| Model | Thickness (mm) | Weight (kg) |

|---|---|---|

| FVTS-01 | 1.5 | 17 |

| FVTS-02 | 2 | 30 |

| FVTS-03 | 2.5 | 35 |

| Materials: SS 304, SS 316, SS 316L, carbon steel. Fixed valves tray can be customized in different dimensions to meet customers' requirements. |

||

Features

Application

Due to its low pressure drop, high efficiency and excellent processing capacity, fixed valves tray is widely used as column internal for mass and energy transfer between gas and liquid, or liquid and liquid.